|

|

|

What We Do…

Using our state of the art equipment and over 90 years of experience working with rubber, we have created over 10,000 unique products — a testament to our ability and resolve to get custom products done right the first time! From coating metal parts with sponge rubber, to making detailed molded products from custom-machined dies, we will work with you and your company to get a high-quality product out on time and within budget.

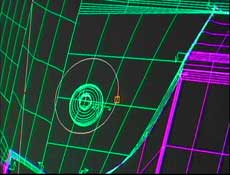

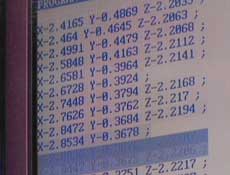

Along with decades of expertise in making specialty rubber and plastic products, our fabrication technology is state-of-the-art: from CAD/CAM design and 3D modeling software to CNC tooling and numerical temperature and pressure controls, we create parts to exacting specifications. Our capabilities include:

• Sponge rubber extrusion: jet black or colored

• Hot or cold splicing

• Dense rubber parts: 25-90 durometer

• Plastic and vinyl extrusions

• Rubber-to-rubber bonding

• PVC vinyl molding and dipping

• Rubber parts with steel cores

• EPDM dense, EPDM sponge, Neoprene, SBR, Silicone, Natural & Plastisol parts

• Textured surfaces to high-gloss finishes

• Hard-as-plastic rubber parts

• Soft to extremely soft rubber parts

• Rough-duty rubber bellows and boots

• Engraving

• Rubber-to-metal vulcanizing

• Sponge-to-rubber or sponge-to-metal bonding